Overview of Seth Thomas Pocket Watches

Despite having produced twenty-four Seth Thomas pocket watch models[1], hundreds of differently “branded” private label pocket watches[15], four factory named grades[1n], and an undetermined quantity of Seth Thomas numbered grades; the Seth Thomas product line can be fairly simple to understand if you look at it from the perspective of the underlying foundational standards to which all of its mechanisms conform.

In the six areas of this section, you will see images and explanations of things that collectors and watchmakers talk about without really defining clearly. This section will help you to understand and organize what might presently seem like a hopeless tangle of confusing information into clearly defined columns and rows; and then we’ll connect the dots together so that you need not miss the forest for the trees.

All of the very general information in this section of the website lays the foundation for understanding the more detailed, specific information in the next section of the website, “Characteristics of Seth Thomas Pocket Watches” that will focus on specification charts and a photo album of specific specimens in each of the twenty-four distinctive Seth Thomas models.

Below you will find an introductory discussion and illustration of basic pocket watch components that will be helpful in understanding the material presented on this website. It’s O.K. if you can’t memorize it yet; just by knowing where to find it you are able to access it when the time is right for you. If you take your time; learning about pocket watches will be more fun than work and can be a happy part of your day!!

Pocket Watch Wheels

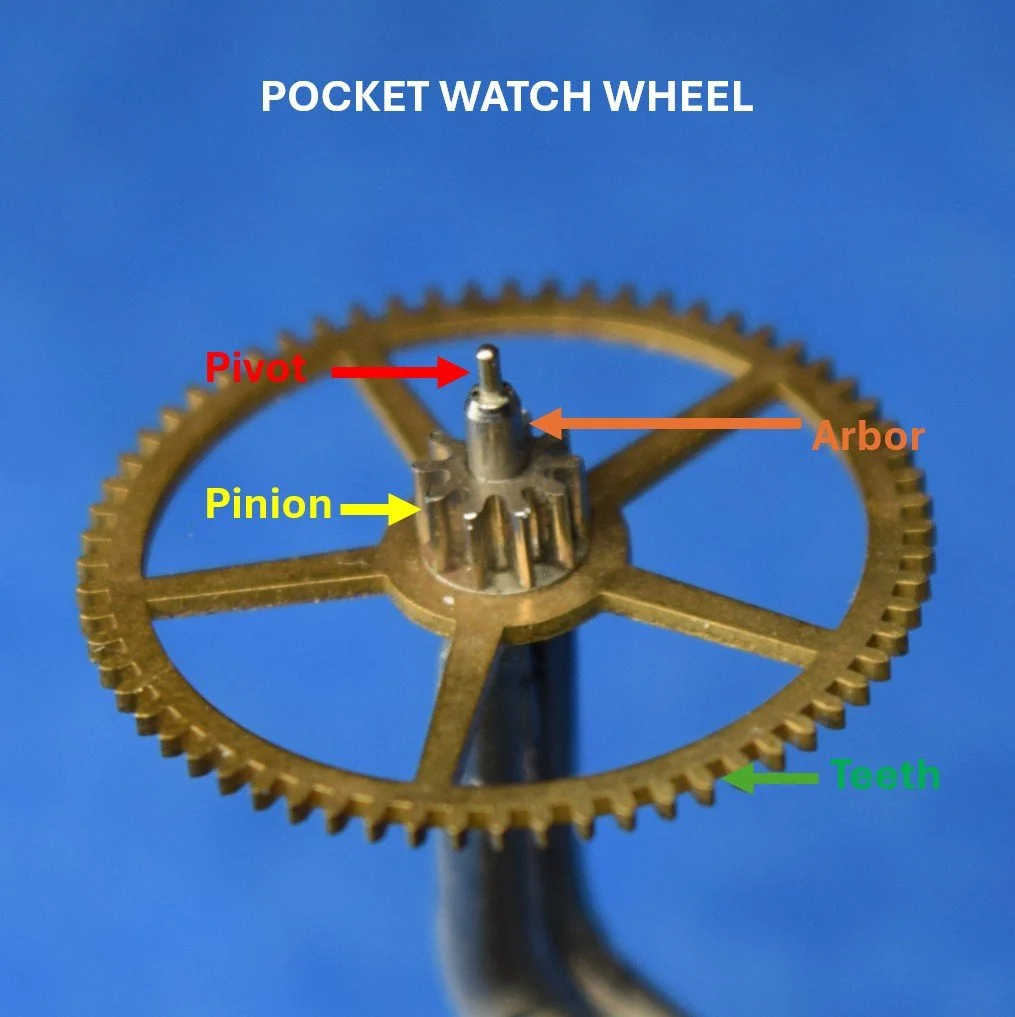

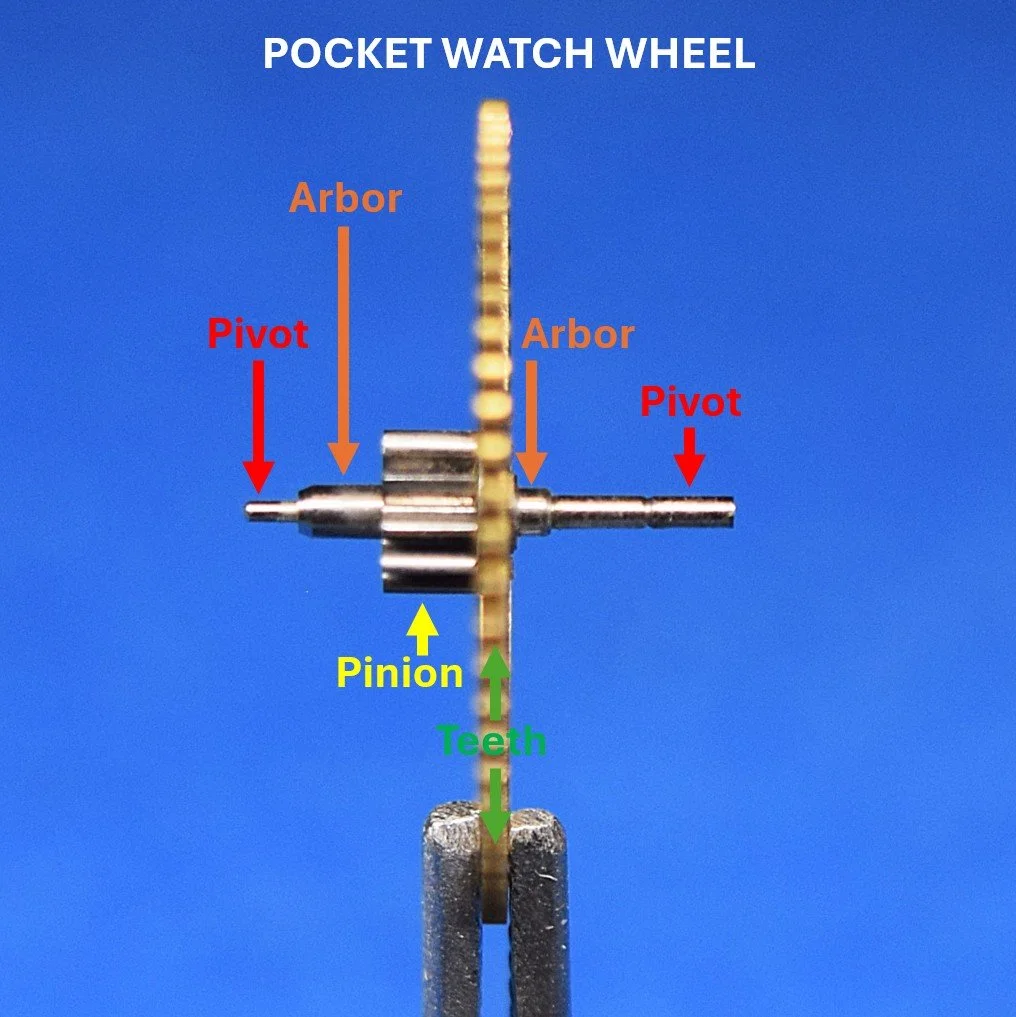

The photographs above show the same pocket watch wheel viewed from above and from the side, allowing the relationship between the wheel, outer teeth, pinion, arbor, and pivots to be seen clearly.

Pocket watch wheels are the means through which energy is moved around inside the pocket watch mechanism. The energy comes from the mainspring that you wind up manually either by using the crown to turn the stem, or by using a key to wind the mainspring directly. The clicking that you hear when you are winding your watch is caused by a component called the “ratchet click” which, by virtue of a spring, bounces off of the teeth of the winding wheel when it turns in the direction to wind the mainspring; but then locks the winding wheel in place so that the energy that you have just wound into the mainspring stays locked in the mainspring until it is released into the pocket watch wheels; so that the pocket watch hands will move at a regulated rate of speed allowing us to use it to know what the time of day is.

You will encounter direct or indirect mention of the components of the pocket watch wheels in the many conversations about pocket watch specifications. Aside from the wheel structure itself, there are really only two general types of components that make a pocket watch wheel function the way that it does. The first type is tooth-like structures, and the other type is axel-like structures. Pocket watch wheels have teeth around their perimeter. They also have teeth on a pinion located at the center of the wheel.

Both sets of tooth-like structures are riding in unison on the second type of structure, the axel-like structure, the arbor. The arbors provide all of the wheels with stable placement between the top plate and the pillar plate, between which they each engage either a neighboring wheel or a regulator component. The arbor is a large comparatively sturdy structure. At either end of the arbor is a smaller specially shaped portion of the arbor, the pivot, that penetrates the top plate or the pillar plate and rides either within a hole in a man-made jewel or a hole (bushing) directly in the metal plate itself. The pivot is shaped and polished to provide less friction between itself and the jewel or the bushing.

Ideally the pivots at both ends of the arbor are riding in the same type of environment, both in a jewel or both in a metal bushing so that wear occurs evenly; but this is not always the case. Several models of Seth Thomas pocket watches jewel the top plate holes; but not the pillar plate holes in their eleven jewel versions. I have a hard time judging the company very harshly about this; after all, a high percentage of all Seth Thomas pocket watches are found to be keeping good time after hundreds of years.

Pocket Watch Power Train

This section is intended as a technical reference that can be revisited as the reader’s understanding develops.

Power Transmission Through the Train

The photograph below shows the components of the pocket watch power train. The power from winding is stored in the Mainspring Barrel. From the teeth of the Barrel Wheel the energy is transmitted to the pinion of the Center Wheel. The teeth of the Center Wheel then pass the power to the pinion of the 3rd Wheel, located beneath the 3rd Wheel. The 3rd Wheel passes the power through its teeth to the pinion of the 4th Wheel which turns the seconds hand. The teeth of the 4th Wheel then pass the power to the pinion of the Escape Wheel.

Regulation of Energy Release at the Escapement

The specially designed teeth of the Escape Wheel bump one jewel on the near end of the Pallet Fork which causes the far end of the Pallet Fork to push the Impulse Jewel located on the roller table of the balance staff. Pushing the Impulse Jewel turns the balance staff and the Balance Wheel. The spring of the Balance Wheel causes the Impulse Jewel to swing back, and it taps the Pallet Fork. By tapping the Pallet Fork out of its locked position with the Escape Wheel, the Escape Wheel is able to move again to release more energy. Through repeated cycles of this process the Balance Wheel effectively regulates the release of energy from the mainspring. This process controls the speed of the watch. The process can be further controlled by the user of the pocket watch, as needed, greatly enhancing the watch’s accuracy.

Rates of Turn

The Center Wheel only makes one full rotation every twelve hours. This allows the hour hand to make one full trip around the dial from 12:00 midnight to 12:00 noon.

The 4th Wheel makes one full rotation every minute. This allows the seconds hand, which is attached to its bottom pivot, to make one full trip around the “seconds bit” every minute. It is the interplay between the components of the regulator and the escape wheel end of the power train which allows this scheduled rate of wheel turning to happen with precise accuracy.